Pre-engineered Metal Buildings

Pre-engineered Metal Buildings

Pre-engineered Metal Buildings (PEBs) are a modern construction solution that combines efficiency and flexibility. A pre-engineered metal buildings, unlike tradition building are constructed from standardised steel components that are pre-fabricated in a factory before being assembled on-site. This approach allows for a streamlined construction process, significantly reducing on-site labour and construction time. Pre-fabricated steel building structures are used across various sectors, including industrial warehouses, commercial spaces, and sports facilities, offering a cost-effective and scalable solution for diverse building needs.

The importance of pre engineered steel buildings lies in their adaptability and efficiency. Their design allows for easy customisation and expansion, accommodating future growth without extensive modifications. Essential features of high-quality PEB building systems include durable steel materials, effective insulation and ventilation systems, and robust load-bearing capacities. These attributes ensure that pre-manufactured steel buildings provide not only structural integrity and energy efficiency but also a safe and comfortable environment for occupants, reinforcing our position among leading pre engineered building manufacturers in India.

With over 40 years of expertise in steel fabrication, we excel in producing pre-engineered products for transmission line towers, telecom towers, and other critical infrastructure. Our capabilities include handling a monthly steel fabrication of 25,000 MT and sourcing an annual 3,00,000 MT of steel, positioning us as India’s leading pre-engineered steel buildings manufacturer. Our comprehensive in-house facilities cover fabrication, shot-blasting, galvanising, painting, quality testing, logistics, and project supervision.

Trusted Pre-Engineered Building Manufacturers for Modern Infrastructure

As one of the top PEB suppliers in India, specializing pre fabrication steel buildings, our product range includes crane beams, mezzanine systems, rafters, I-beams, foundation bolts, purlins & girts, eave struts, pipe bracings, sag rods, flange bracings, and more. We also offer profiling for roofing and cladding systems with Galvalume sheets of 0.47 mm, 0.5 mm, and 0.6 mm thickness, featuring 345 MPa or 550 MPa yield strength.Our Pre-engineered Metal Buildings (PEB) are ideal for various prestigious private and public sector projects, including industrial sheds, warehouses, multi-storey buildings, and cold storage spaces. Designed as efficient pre engineered metal building solution, they are environmentally friendly too, as they do not require water during construction. With a focus on structural strength, efficiency, and timely execution, we continue to be recognised among dependable pre engineered building manufacturers in India.

-

40

Years of Experience

-

3428090

Infrastructure & Manufacturing Setup

-

25000

Monthly Steel Fabrication

-

300000

Annual Steel Procurement

Product Specification

Product Specification

- Primary Standards: IS, AISC, MBMA (HR/Built-ups)

- Secondary Standards: IS 801, AISI (Cold form)

- Roof Live Load Standards: IS 875, MBMA

- Wind Load Standards: IS 875, MBMA

- Seismic Load Standards: IS 1893

- Collateral Load: IS 875

- Deflection limits: IS 800 / MBMA

- Manufacturing / Erection Tolerances: MBMA

- Products: IS 2062 / ASTM 572 Standards

- Welding: AWS D.1.1M

- High Durability: Our Pre-engineered steel buildings offer exceptional durability, ensuring long-term performance even in harsh conditions. Their robust steel construction withstands wear and tear, providing lasting value.

- 100% Recyclable: PEBs are environmentally friendly, being 100% recyclable. This sustainable feature minimises waste and supports eco-friendly practices, aligning with modern green building standards.

- Customised: As one of the leading PEB building manufacturers in India, we offer solutions that can be customised to meet specific needs and preferences. This flexibility allows for tailored designs that cater to diverse architectural and functional requirements.

- Can Be Relocated with Minimal Wastage: One of the advantages of pre fabricated steel building structures is their ability to be relocated with minimal wastage. This feature offers adaptability and cost-effectiveness for changing business needs.

- Applicable in Low-Rise, Medium-Rise, and High-Rise Buildings: Pre-manufactured steel buildings are versatile and suitable for a range of building types, from low-rise warehouses to high-rise commercial structures, both in India and internationally.

- Precision Fabrication Using Automation: PEBs are crafted with precision through automation in a controlled environment. This ensures high-quality fabrication and adherence to strict quality standards.

- Strict Quality Standards: Our pre engineered metal building structures adhere to rigorous quality standards, both for raw materials and fabricated products. This commitment ensures structural integrity and reliability throughout the building's lifecycle.

- Economy: Our Pre-Engineered Buildings (PEBs) provide significant cost savings through efficient material usage and reduced labour costs. Their economical design minimises overall project expenses while maintaining high quality.

- Timely Delivery: With our streamlined manufacturing and assembly processes, we ensure timely delivery of pre-engineered steel buildings. This punctuality supports project schedules and enhances overall efficiency.

- Faster Construction: PEB structures accelerate construction timelines thanks to pre-fabrication and efficient assembly. This quick turnaround helps in meeting tight deadlines and reduces time-to-market for your project.

- Endurance to Cyclonic Storms: Our pre engineered steel buildings are engineered to withstand cyclonic storms. They offer robust protection and structural integrity in severe weather conditions, ensuring safety and reliability.

- Endurance to Earthquake: Designed to endure seismic activities, our Pre-Engineered Buildings (PEBs) incorporate features that enhance earthquake resistance. This ensures stability and resilience in earthquake-prone areas.

- Usage of Recyclable Materials: Our pre engineered metal buildings utilise recyclable materials, aligning with sustainable building practices. This eco-friendly approach supports environmental conservation and reduces the carbon footprint of your construction.

- Customisable Designs: We offer customisable Pre-Engineered Buildings (PEBs) tailored to specific needs. This flexibility allows for unique architectural solutions and functional adaptability for diverse applications.

-

Adherence to Engineering Codes:

Our Pre-Engineered Buildings (PEBs) adhere strictly to current engineering codes and standards. These include:

Primary (HR / Built-ups) : IS / AISC / MBMA

Secondary (Cold form) IS: 801 / AISI

Roof live load: IS / MBMA

Seismic loads: IS 1893 (Part 1)

Collateral Load: IS

Deflection limits: IS / MBMA

Manufacturing and Erection tolerances: MBMA

Welding AWS D.1.1M

This ensures compliance with regulatory requirements and upholds the highest technical and safety benchmarks. -

Durability & Versatility

Durability & Versatility The durability and versatility of our pre-fabricated steel buildings make them suitable for various applications. They provide long-lasting performance and adaptability, meeting diverse structural and functional needs.

As one of the best Pre-Engineered Buildings (PEB) manufacturers in India, we have an in-house Engineering Team, comprising Structural Design Engineers, Draftsmen, Production Engineers, Planning Engineers, Quality Engineers and Project Engineers who follow the latest design codes and technical compliances for designing, manufacturing and installing all components in any Pre-Engineered Metal Buildings.

Application Areas

Application Areas

Discover the widespread applications of our Pre-engineered Metal Buildings, which provide essential illumination and safety in both urban and rural settings. From residential streets and highways to parks and parking lots, our durable and aesthetically pleasing poles enhance visibility and promote community well-being, ensuring long-lasting and reliable outdoor lighting.

-

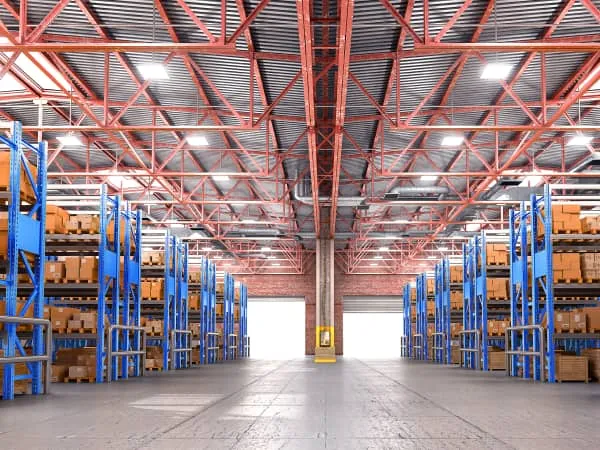

Industrial warehouses

-

Storage spaces

-

Industrial sheds

-

Office spaces

-

Hangars

-

Cold storage facilities

-

Factories

-

Plant buildings

-

Airport sheds

-

Railway car sheds

-

Sports auditoriums

-

Stadium structures

-

Multi-storey buildings

-

Low-rise to Skyscrapers

-

Data centers

Our Projects

Our Projects

Discover our successful ventures across diverse industries. Each project highlights our commitment to quality, adherence to timelines, and client satisfaction. Explore our achievements in delivering high-quality pre engineered metal building solutions and pre engineered steel building as trusted pre engineered building manufacturers in India.

Celebrity Breweries

Located in Dhaniakhali, West Bengal, this 1470 sq. mtr production unit was completed in just 3 months. Despite challenges, we ensured precise adherence to the 3D design view, timely delivery of materials, and efficient erection.

The project included M.S. plates, tubes, and quality paints, with a building height of 7.5 metres. Our commitment to high standards and rigorous quality checks resulted in a seamless execution and satisfied client needs.

N. S. Power

Situated in Dumka, Jharkhand, this 2261.42 sq. mtr manufacturing unit was completed in 5 months. We tackled the project by maintaining rigorous compliance with the 3D design view, ensuring prompt material supply, and executing the erection process with precision.

The building, with heights varying from 7.142 to 14.575 metres, featured M.S. plates, cold-form sections, and other high-quality materials. Our efficient project management and dedication to quality resulted in a successful delivery and client satisfaction.

Market Growth

Market Growth

The Pre-engineered Metal Buildings (PEB) industry is experiencing significant growth, driven by increasing demand across various sectors. In 2022, the market was valued at USD 12,071.0081 million, and it is projected to surge to USD 30,019.92548 million by 2030. This remarkable growth represents a compound annual growth rate (CAGR) of 13.90% during the forecast period from 2024 to 2030. Similarly, in 2019, the global pre-engineered building market was valued at USD 14.5 billion and is expected to reach USD 25.0 billion by 2024, growing at a CAGR of 11.5%. These statistics indicate a robust expansion in the industry, highlighting the growing reliance on PEBs across various construction projects.

The market's upward trajectory is further evidenced by recent projections that valued the PEB market at USD 17.6 billion in 2022. By 2032, this figure is expected to nearly triple, reaching USD 46.6 billion, with a CAGR of 10.4%. This steady growth is primarily driven by the increasing construction of commercial, industrial, and residential spaces. As businesses and individuals seek cost-effective and efficient construction solutions, pre-manufactured steel buildings offer a compelling alternative due to their faster construction timelines, flexibility in design, and lower overall costs compared to traditional building methods.

Another key factor propelling the PEB market is the rising preference for sustainable sourcing and materials with low environmental impact. With a growing emphasis on green construction practices, PEBs are gaining traction as they align with global efforts to reduce carbon footprints. The use of recyclable materials and energy-efficient designs in pre fabricated steel buildings makes them a popular choice for environmentally conscious developers and companies aiming to meet stringent sustainability goals.

Moreover, the integration of advanced technologies, such as automation in fabrication processes and smart building solutions, is enhancing the appeal of pre-manufactured steel buildings. These innovations not only improve the efficiency and precision of construction but also offer long-term benefits in terms of maintenance and operational costs. As the industry continues to evolve, PEBs are set to play an increasingly vital role in shaping the future of construction. As the leading PEB supplier in India, we are all set to make a difference in this sector.

Related Products

Related Products

Discover our comprehensive range of infrastructure solutions, built to deliver unmatched strength, consistent reliability, and lasting performance.

Manufacturing Process

Manufacturing Process

Our rigorous and research-backed manufacturing process for each section of Pre-engineered Metal Buildings (PEB), including pre engineered metal building systems, involves the highest quality raw materials and ensures export-grade outputs at every stage of production: Manufacturing for Build-up Sections (H-beams)

-

Slitting of HR Coils

HR coils are split into desired widths according to the requirements.

-

Marking Plan (as per Fabrication Drawings)

The slit HR coils are marked according to the fabrication drawings.

-

Cutting of HR Plates through Plasma Cutting Machine

HR plates are cut using a plasma cutting machine, following the marked plan.

-

Continuous Welding (SAW) on One Side using PTW Machine

Continuous welding is performed on one side using a PTW machine with Submerged Arc Welding (SAW).

-

Stitch Welding (MIG) on Another Side using Rectifiers and Stick Electrodes

Stitch welding is performed on the other side using Metal Inert Gas (MIG) welding with rectifiers and stick electrodes.

-

Surface Preparation through Shot Blasting Machine

The welded sections undergo surface preparation using a shot blasting machine.

-

Application of Red Oxide Primer (for Synthetic Enamel Paint) / Epoxy Primer (for Epoxy Paint)

A red oxide primer or epoxy primer is applied depending on the type of final paint.

-

Application of Synthetic Enamel Paint / Epoxy Paint

Finally, synthetic enamel paint or epoxy paint is applied to the prepared sections. Manufacturing for Cold-formed Sections (C-Purlins, Z-Purlins, Flange Bracings)

- Manufacturing for Cold-formed Sections (C-Purlins, Z-Purlins, Flange Bracings) GP coils are slit into the required widths.

- Roll Forming through PLC-controlled Roll Forming Machine The slit coils undergo roll forming through a PLC-controlled roll forming machine to achieve the desired shapes.

Manufacturing for Hot-rolled Sections (SHS, CHS, Rods, ISA, ISMB, ISMC)

- Cutting of Hot Rolled Sections (as per Dimensions Given in Fabrication Drawings) Hot rolled sections are cut to the specified dimensions according to the fabrication drawings.

- Application of Red Oxide Primer (for Synthetic Enamel Paint) / Epoxy Primer (for Epoxy Paint) A red oxide primer or epoxy primer is applied depending on the type of final paint.

- Application of Synthetic Enamel Paint / Epoxy Paint Application of Synthetic Enamel Paint / Epoxy Paint

Manufacturing for Profiled Galvalume Sheets, Trims, Flashings, Gutters, Downlake Pipes

- Profiling using Profiling Machine Galvalume sheets and other components are profiled using a profiling machine to achieve the desired shapes.

Quality Policies

Quality Policies

Our commitment to quality is unwavering. We leverage cutting-edge infrastructure, stringent quality control measures, and robust production capacity to deliver industry-leading solutions. As a trusted PEB supplier in India, Utkarsh India adheres to the strictest IS, BS, ASTM, AS, EN, OHSAS, MORTH, and SLS norms, partnering with global testing labs like SGS, CE, DNV, BVQI, and TUV.

-

Our five in-house 12.5m Hot Dip Galvanising facilities use 99.995% pure zinc from Hindustan Zinc Limited, ensuring superior coating quality and a flawless finish on all products.

-

Our QA/QC team ensures thorough quality checks at every production stage, from raw material procurement to dispatch, maintaining high standards for our solar panel poles.

-

As a leading Solar pole manufacturer, we produce over 2000 MT monthly and maintain a stock of 1000 MT, ensuring timely delivery of solar poles across India..

-

Our quality policies include strict adherence to delivery schedules, ensuring that PEBs reach our clients on time, meeting project deadlines and requirements. This same commitment extends across all our verticals, including our role as a pre engineered steel buildings manufacturer, where timely delivery is critical to supporting large-scale infrastructure projects.

FAQs

FAQs

Pre-Engineered Buildings (PEB) are structures that are designed, fabricated, and assembled using standardised components manufactured in a controlled factory environment and then transported to the construction site for assembly. Unlike traditional construction methods, which involve on-site fabrication and assembly of structural components, PEBs offer faster construction timelines, cost savings, and greater design flexibility.

Pre-engineered metal buildings offer several advantages that make them a preferred choice in construction projects. One major benefit is their faster execution, as they are built partially in a factory and then assembled on-site, expediting the project timeline. Additionally, they are cost-effective due to their construction in a controlled factory environment, resulting in savings in both time and money. PEBs also require low maintenance, thanks to their use of high-quality materials like steel that resist rust and corrosion. This durability extends to their superior strength, allowing them to withstand harsh weather conditions and making them suitable for a wide range of applications, from warehouses to airport terminals and cold storage facilities.

Indeed, Pre-Engineered Steel Buildings are renowned for their strength and durability. When meticulously designed with high-quality materials, they exhibit resilience against earthquakes and various natural disasters. Nevertheless, the longevity of these structures hinges on several factors including: the intended purpose guiding their design, the quality of materials employed during manufacturing, the specific design elements incorporated into the Pre-Engineered Buildings (PEB), and the advanced technologies utilised in their fabrication.

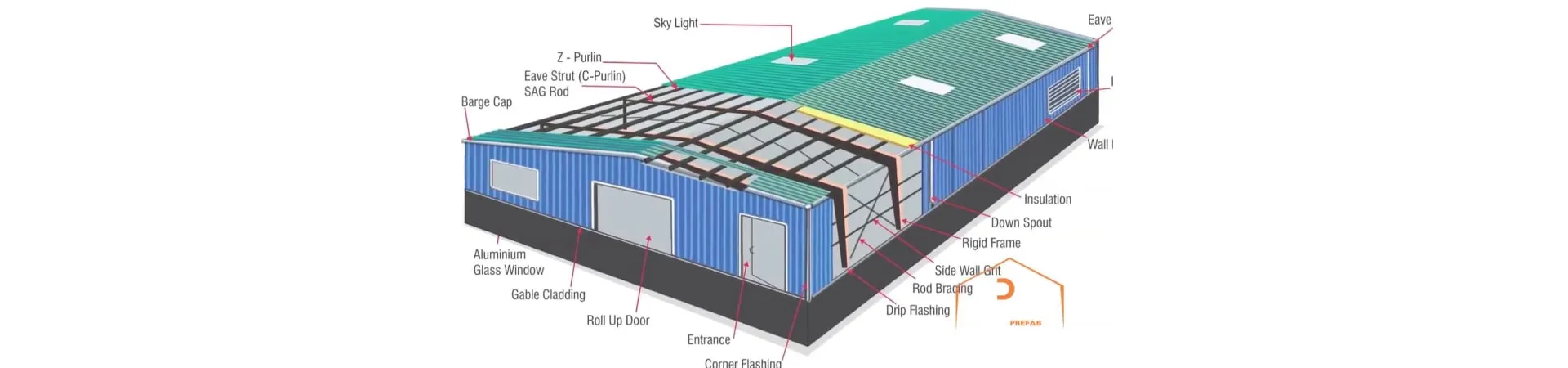

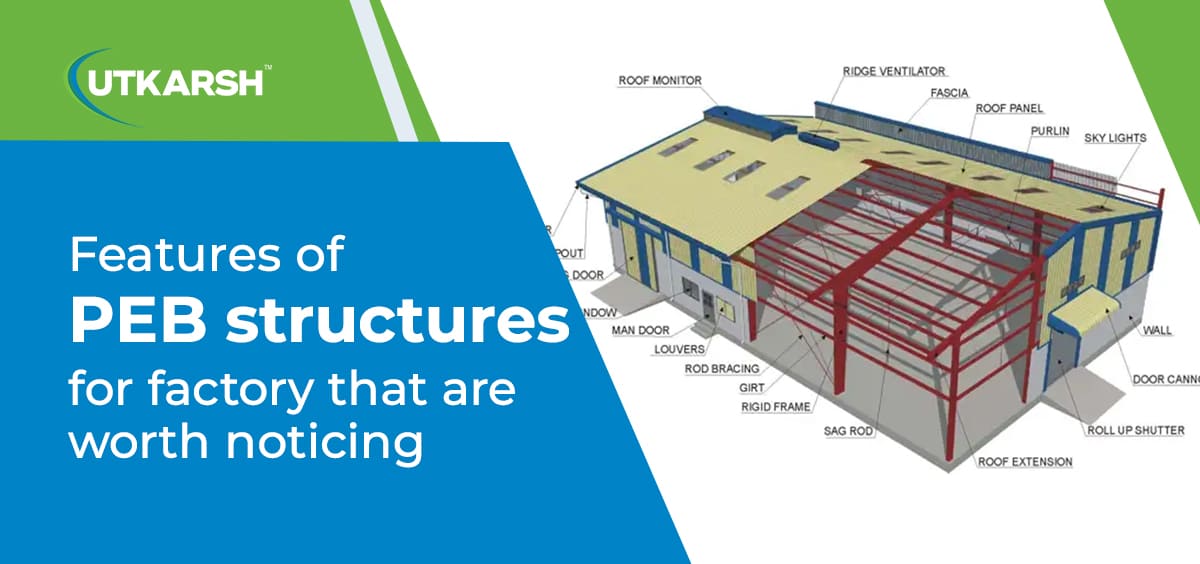

Our pre manufactured steel buildings are composed of several key components that work together seamlessly. These include primary members or main frames, which form the structural backbone of the building, providing support and stability. Secondary members, often in the form of cold-formed members, complement the primary members and contribute to the overall structural integrity. Roof and cladding systems play a crucial role in protecting the building from environmental elements while also enhancing its aesthetic appeal. Additionally, deck accessories such as fasteners and connectors ensure that all parts of the building are securely connected and function as intended. Together, these components form a robust and efficient system that is well-suited for a variety of construction projects.

Pre-fabricated steel buildings offer a wide range of customisation options, including size, shape, design, layout, and finishes. Customers can choose from various roofing and wall systems, insulation options, doors, windows, and accessories to tailor the building to their specific requirements. Additionally, pre-engineered buildings (PEB) can be easily expanded or modified to accommodate future growth or changes in operational needs.

Our Pre-Engineered Buildings (PEB) are primarily constructed using high-quality materials like steel, which offers exceptional strength, durability, and versatility. The structural components of our Pre-Engineered Buildings (PEB), including columns, beams, and roof trusses, are fabricated from steel to ensure structural integrity and resistance to environmental factors.

The most common applications of Pre-Engineered Buildings (PEB) include office spaces, hangars, cold storage facilities, factories, plant buildings, airport sheds, railway car sheds, sports auditoriums, stadium structures, and multi-storied steel buildings.

With decades of high-end manufacturing experience, we stand a class apart from the competition. Our proven expertise in critical fabrication, and a proud track record of having our products installed in mega projects worldwide, reinforce our position as a leading pre engineered steel buildings manufacturer, known for quality, innovation, and excellence in PEB manufacture services.

The construction timeline for pre-engineered buildings (PEB) depends on various factors, including the size and complexity of the project, site conditions, and customization requirements. However, Pre-Engineered Buildings (PEB) typically have shorter construction timelines compared to traditional construction methods due to off-site fabrication and assembly of components. On average, Pre-Engineered Buildings (PEB) can be completed in a fraction of the time required for conventional construction, resulting in faster occupancy and return on investment for the client.

Utkarsh India maintains strict quality assurance measures throughout the design, fabrication, and installation process of Pre-Engineered Buildings (PEB). Our manufacturing facilities are equipped with advanced technologies and quality control systems to ensure that all components meet industry standards and specifications. Additionally, our experienced engineers and project managers oversee every aspect of the project to ensure compliance with quality and safety requirements.

Our Pre-Engineered Buildings (PEB) are environmentally friendly and sustainable construction solutions. They require fewer resources and generate less waste compared to traditional construction methods, resulting in reduced environmental impact. Additionally, Pre-Engineered Buildings (PEB) can incorporate energy-efficient features such as insulation, natural lighting, and renewable energy systems to further minimise their environmental footprint.

The Utkarsh India Steel brochure is available for download in PDF (Portable Document Format) files. Click here to access the available brochures and download them.

Why Choose Utkarsh India

Why Choose Utkarsh India

-

With over 40 years of experience, Utkarsh India stands as a leading PEB manufacturer, excelling in steel fabrication, rolling, and forming for diverse pre-engineered building materials.

-

We are among the few in India with the highest steel fabrication capacity, producing over 25,000 MT/month, and procuring more than 300,000 MT of steel annually to meet growing demand.

-

Our extensive portfolio includes critical fabrications like transmission line towers, telecom towers, and railway electrification, with installations in major global projects.

-

From fabrication to galvanising, testing, painting, and installation, our fully integrated facilities ensure top-tier quality control and seamless project execution.

-

Trusted by leading contractors and EPC players, our pre-engineered building materials are part of several high-profile national and international projects, reflecting our industry leadership.