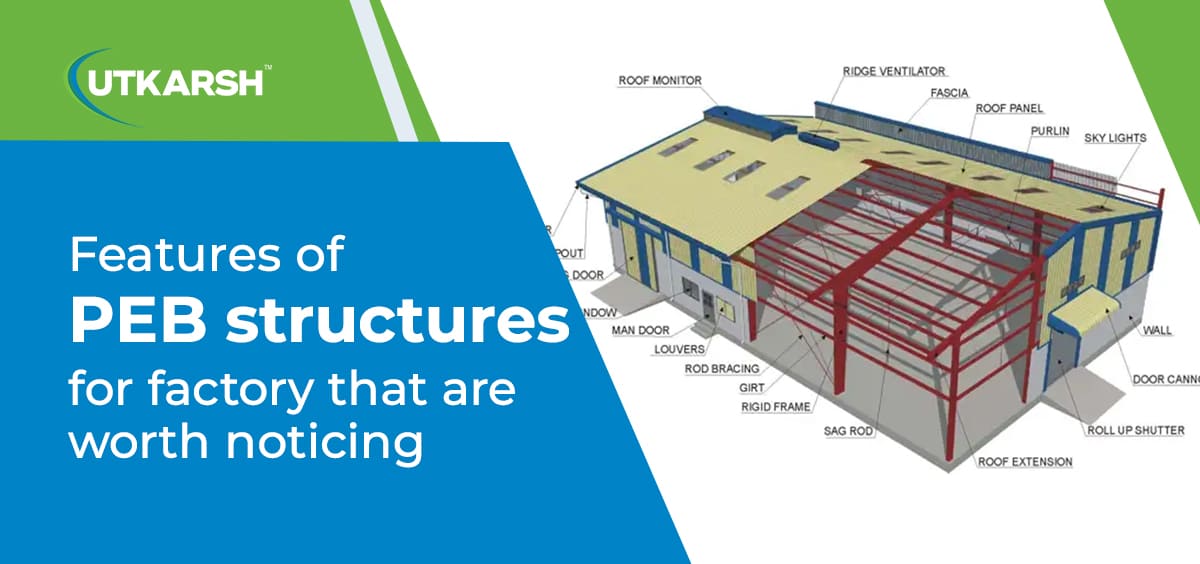

Features of PEB Structures for Factory that are Worth Noticing

If you are planning to build a factory, PEB structures are worth considering. PEB structures for factory are highly customisable and can be designed as per specific size, shape, and load-bearing requirements. Here are some of the features of PEB structures for factory that are worth noticing:

-

Durability:

PEB structures for factory are known for their excellent durability. Built of steel I-frames, high-quality galvanized steel products , the PEB structures are sturdy and are designed to withstand extreme weather conditions. Not just that, steel is resistant to fire, rot, and pests. This makes them a suitable option for use in factories, where the building will be subjected to heavy usage, forklifts and other machinery, and 24/7 operation.

-

Cost-effective:

When it comes to cost, PEB structures for factory offer many benefits. As steel is lightweight and yet has high strength, the amount of material required is less. This lowers the overall cost. Moreover, the pre-planning software used helps in optimising material requirements. When you build a traditional concrete structure, there are several variables that delay the construction and increase the cost. In the PEB structures for factory are built in a controlled environment and, therefore, the condition of the site or other variables are less likely to affect the process. Moreover, the installation cost involved is also low.

-

Higher precision:

Made using advanced software and manufacturing techniques, PEB for factory structures offer higher precision and accuracy in comparison to traditional building methods. Using the software, PEB structures can be designed to suit projects that require complex designs. We use STAAD PRO (VI8) and TEKLA software for designing and detailing.

-

Load bearing capacity:

One of the key things that makes PEB structures ideal for factories is that the advanced engineering principles and techniques allow conducting load-bearing simulations. These simulations are used to evaluate the structural integrity of the building and ensure that it can withstand various loads and stresses. Simulations allow engineers to model the behaviour of the structure under different loading conditions, such as wind, snow, and seismic forces. The simulations take into account the size and shape of the structure, and the location of the building.

Our PEB structures for factories adhere to IS standards . It shows how well a PEB structural shed is designed to handle roof life load, wind loads, seismic loads and collateral load.

-

Relocatable:

The steel components that make up PEB structures for factory can be taken apart and reassembled at a new location. This makes PEB structures a cost-effective solution as they can be reused, rather than having to construct a new building.

-

Recyclable:

One of the advantages of PEB structures is that they can be designed to be easily disassembled and recycled. This is because they are made up of a modular system of steel components that can be easily taken apart and reused.

-

Low maintenance:

Galvanised steel is a low maintenance building material that is known for its durability and longevity. It is resistant to corrosion, fire, and pests, making it a popular choice for PEB structures for factory.

Looking for PEB warehouse manufacturers?

We offer you PEB steel structures made of galvanised sheets conforming to grade standards IS2062 and ASTM572. Our PEB structures are highly durable and undergo stringent quality tests before they are dispatched. To ensure that our PEB structures are of high quality, we have a beam welding machine as well as 10 in-house testing labs. We also offer installation and technical advisory. We deliver across India and have a 24x7 logistic and dispatch department for quick turnaround time. To generate a quote, contact us.