ERW Hollow Section

ERW Hollow Section

ERW Hollow Sections are Electric Resistance Welded (ERW) steel pipes that are characterised by their square or rectangular cross-sections. These sections are produced through a welding process that joins steel coils together, forming a continuous tube. The significance of ERW Hollow Sections lies in their structural integrity and versatility, making them essential components in various industries such as construction, infrastructure, automotive, and general engineering. Their ability to withstand high loads, along with their ease of fabrication, makes them ideal for applications that require both strength and durability.

The uses of electric resistance welded pipes are vast, encompassing everything from building frames, scaffolding, and bridges to industrial machinery and transportation systems. These hollow sections are crucial in structural applications where weight reduction, corrosion resistance, and high tensile strength are key requirements. Their design allows for efficient load distribution and reduces material wastage, making them a preferred choice for engineers and architects alike.

When selecting ERW Hollow Sections, certain must-have features should be considered to ensure optimal performance. These include high tensile strength, precise dimensional accuracy, superior surface finish, and excellent weldability. Additionally, resistance to corrosion and harsh environmental conditions is essential, particularly for applications in coastal or industrial areas. The use of high-quality raw materials, such as those sourced from reputable suppliers like TATA and SAIL, further enhances the durability and reliability of these sections.

At Utkarsh India, we take pride in being a leading ERW pipe manufacturer in India, delivering top-quality ERW Hollow Sections that meet both national and international standards. Our range of square and rectangular hollow sections is crafted with precision and reliability, making them ideal for a variety of applications. From construction and infrastructure projects to general engineering purposes, our products are designed to perform in the most demanding environments.

Our ERW Hollow Sections are available in a wide range of sizes, starting from 15 mm to 400 mm in diameter with thicknesses ranging from 2 mm to 10 mm. We offer square sections from 19 x 19 mm to 260 x 260 mm, and rectangular sections from 50 x 25 mm to 172 x 92 mm. This extensive range allows us to cater to diverse industry needs, making Utkarsh a trusted ERW pipe supplier for companies across India and beyond.

Our manufacturing process is driven by advanced technology and stringent quality control. With 6 high-speed tube mills, 2 slitting lines, and a 7-tank galvanisation process, we ensure that every electric resistance welded pipe produced at our facilities meets the highest standards of durability and performance. Our products are approved by renowned certification authorities like BHEL, PHE, PWD, SGS, CE, DNV, BVQI, TUV and many more, ensuring that we consistently deliver high-quality solutions.

As a recognised leader in the ERW pipe manufacturing sector, we are committed to excellence in every aspect of our operations. Our dedicated spectrometer lab ensures that each product meets the required chemical composition, while our rigorous testing procedures guarantee that every pipe meets the stringent requirements of the industries we serve. With a strong focus on customer satisfaction, Utkarsh India continues to set the benchmark for ERW Hollow Sections and other steel tube products in the industry.

-

140000

Annual Production Capacity

-

6

High Speed Tube Mills

-

100

High Speed Tube Mills

Product Specification

Product Specification

- Precision Dimensions: Our ERW Hollow Sections are available in sizes from 15mm to 400mm, ensuring accurate dimensions for diverse applications.

- High-Grade Steel: Crafted from premium-grade steel sourced from SAIL and TATA, ensuring superior strength and durability in every ERW pipe.

- Galvanisation Process: Utilises a 7-tank hot-dip galvanization process, ensuring exceptional corrosion resistance and longevity for all ERW Hollow Sections.

- Thickness Range: Offering thicknesses from 2mm to 10mm, our ERW pipes provide robust support for structural and industrial applications.

- Length Range: Random length: 4-7m, exact length as per customer’s choice, with a tolerance of +6mm.

- Compliance Standards: Manufactured in accordance with IS 4923:1997, our ERW Hollow Sections meet both national and international quality standards.

- Advanced Production: Produced using high-speed tube mills and in-house testing, ensuring precision and consistency in every electric resistance welded pipe.

- Surface Finish: Featuring a smooth, high-quality finish that enhances the aesthetic and functional performance of our ERW pipes.

- Superior Material Quality: Manufactured using high-grade steel from leading suppliers, our ERW hollow sections ensure enhanced durability and performance for various applications.

- Precision Engineering: Our ERW hollow sections are engineered with exacting standards, offering precise dimensions and exceptional consistency, crucial for structural integrity and reliability.

- Corrosion Resistance: Coated with advanced galvanising techniques, our electric resistance welded pipes resist corrosion, extending the lifespan and reducing maintenance needs for diverse environments.

- Versatile Applications: Ideal for a wide range of applications including structural support, construction, and engineering projects, our ERW hollow sections offer flexibility and durability.

- Compliance Standards: Our products adhere to national and international standards, including IS, BS, and ASTM, ensuring quality and safety as an ERW pipe supplier.

- Cost-Effective Solutions:With optimised production processes, we provide competitively priced ERW hollow sections without compromising on quality, offering cost-effective solutions for various projects.

- Timely Delivery: Backed by efficient manufacturing and streamlined logistics, we ensure prompt delivery of ERW hollow sections. As a trusted ERW Pipe supplier, we are committed to meeting project deadlines and fulfilling customer demands without compromising on quality.

- Hydro Tested for Leakproofness: Every electric resistance welded pipe undergoes hydro testing at 5 MPA (50 bar) to ensure complete leakproofness, along with additional Eddy Current testing during the mill operation for enhanced quality control.

- Custom Surface Coatings: Available in bare, zinc-coated, or other surface coatings based on customer preferences, providing flexibility for specific applications and protection against environmental factors.

- Customised Length & End Conditions: Our ERW hollow sections can be tailored to custom lengths and end conditions, ensuring the perfect fit for diverse customer needs and project specifications.

- Enhanced Durability: Our ERW hollow sections are built to withstand harsh conditions, ensuring long-lasting performance as a trusted ERW pipe supplier.

- Precision Engineering: Manufactured with precision, our electric resistance welded pipes offer consistent quality and dimensional accuracy, ideal for various structural applications.

- Versatile Applications: Suitable for a wide range of uses, our ERW hollow sections are perfect for structural frameworks, construction, and more.

- Superior Strength: Engineered to deliver high strength and load-bearing capacity, our ERW pipes excel in demanding industrial environments.

- Cost-Effective Solutions: Providing excellent value for money, our ERW hollow sections are competitively priced without compromising on quality.

- Quality Assurance: As a leading ERW pipe manufacturer in India, we adhere to strict quality control standards, ensuring reliable and high-performance products.

- Rapid Delivery: As a trusted ERW Pipe supplier, our efficient production and supply chain processes ensure the timely delivery of ERW pipes, helping you meet project deadlines with ease.

Application Areas

Application Areas

ERW hollow sections manufactured by Utkarsh India are designed for usage in diverse applications. Ideal for construction, infrastructure, and structural uses, our electric resistance welded pipes are highly versatile, underlining our position as a leading ERW pipe manufacturer in India.

-

Construction Frameworks

-

Industrial Applications

-

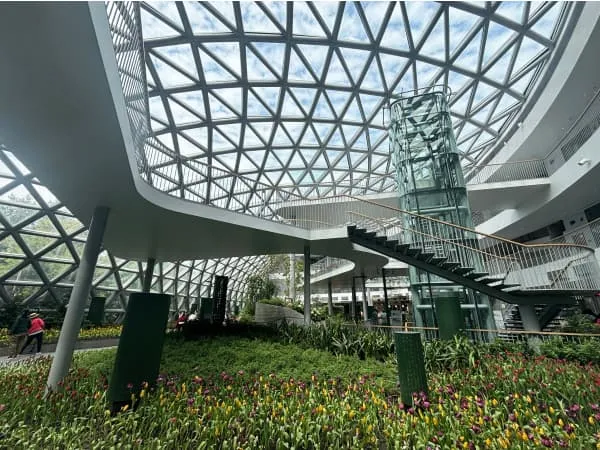

Infrastructure Projects

-

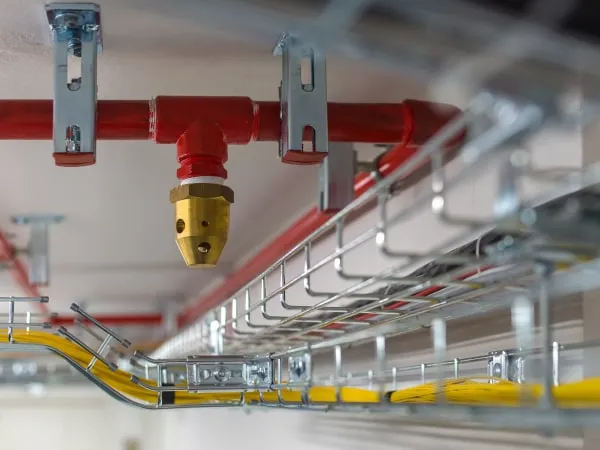

Firefighting Systems

-

HVAC Systems

-

Furniture & Domestic Applications

-

Automotive Chassis & Cabins

-

Bus Stands & Milk Booths

-

Scaffoldings & Storage Racks

-

Furniture Partition Framework

-

Guard Rails & Hand Railings

-

Fencing Poles & Platforms

-

Truck & Bus Body Members

-

Staircases & Trusses

-

Columns, Purlins & Trolleys

Our Projects

Our Projects

Hindustan Petroleum, Visakhapatnam

Provided 20 MT MS ERW pipes for plant maintenance, supporting efficient operations at Hindustan Petroleum Corporation Limited.

Power Grid Corporation, Jammu & Kashmir

Delivered 24 MT MS ERW pipes for Power Grid Corporation Project, aiding efficient power distribution.

DVC Bokaro, Jharkhand

Supplied 128 MT MS ERW pipes for DVC Bokaro Thermal Power Project, ensuring reliable plant operations.

NTPC Vindhyachal, Madhya Pradesh

Delivered 9.5 km MS ERW pipes for plant maintenance, aiding NTPC Vindhyachal's infrastructure projects.

NALCO Angul, Odisha

Delivered 30 MT MS ERW pipes for plant maintenance at NALCO Angul, enhancing operational efficiency.

JJM Project, Tripura (Agartala)

Delivered 100 km MS ERW pipes for drinking water solutions under JJM, addressing water needs in Agartala.

NTPC Raebareli, Uttar Pradesh

Supplied 16 MT MS ERW pipes for NTPC Raebareli plant maintenance, supporting infrastructure reliability.

Market Growth

Market Growth

The ERW (Electric Resistance Welded) Steel Pipes and Tubes market is on a robust growth trajectory, with a significant increase expected in the coming years. Valued at USD 24.40 billion in 2023, the market for ERW pipes and tubes is projected to reach USD 32.86 billion by 2030, reflecting a compound annual growth rate (CAGR) of 4.17% from 2024 to 2030. This upward trend highlights the growing importance of ERW products across various sectors.

The anticipated market growth is supported by strong demand across multiple industries, including manufacturing, construction, oil and gas, infrastructure, and transportation. ERW Pipe Manufacturer capabilities play a vital role in meeting this demand, as ERW pipes and tubes are crucial for transporting solids, liquids, and gases efficiently and safely. This broad application base underscores the versatility and essential nature of ERW products in modern industrial processes and infrastructure development.

Furthermore, the global structural steel tube market, which encompasses ERW hollow sections, is also experiencing notable expansion. Valued at USD 105.3 billion in 2023, it is projected to grow to USD 167.5 billion by 2033, driven by a similar CAGR of 4.8%. This growth is indicative of the increasing reliance on structural steel tubes for diverse applications, including construction and infrastructure projects, where strength and durability are paramount.

The rise in market size and expansion is also fueled by a heightened awareness of the benefits associated with ERW steel pipes and tubes. These products offer exceptional strength, cost-effectiveness, and versatility, making them an attractive choice for a range of applications. As industries continue to prioritise efficient and reliable solutions, a trusted ERW Pipe supplier becomes essential in meeting this growing demand—reinforcing the critical role ERW pipes and tubes play in supporting various industrial and infrastructural needs.

Related Products

Related Products

Discover other top-quality products from our range that are customised to meet your needs and exceed expectations. Explore now!

Manufacturing Process

Manufacturing Process

We follow a comprehensive manufacturing process for ERW pipes and tubes, ensuring high quality and precision. From raw material selection to final testing, we adhere to strict standards to deliver excellence.

-

H.R. Coil / H.R. Section

The process begins with the selection and preparation of high-quality hot-rolled (H.R.) coils or sections, which serve as the primary raw material for our steel tubes and pipes.

-

Planning

Detailed planning is undertaken to optimise production efficiency, allocate resources effectively, and meet customer requirements.

-

Slitting Coil / Shearing HR Section

The raw material undergoes slitting or shearing to achieve the desired width and dimensions, ensuring uniformity and consistency in our products.

-

Production

The production phase involves various operations such as rolling, embossing, stamping, cutting, shearing, bending, welding, and notching, each meticulously executed to meet design specifications and quality standards.

-

N.D.T. & Other Testing

Non-destructive testing (N.D.T.) and other quality checks are conducted at various stages of production to ensure the integrity and reliability of our steel tubes and pipes.

-

Varnishing / Painting

To enhance durability and corrosion resistance, the tubes and pipes may undergo varnishing or painting, providing additional protection against environmental factors.

-

End Formation / Hill Grinding / Base Plate Fitting

End formations, hill grinding, and base plate fittings are carried out as per customer requirements, ensuring compatibility with installation needs and facilitating ease of use.

-

Inspection

Comprehensive inspections are conducted throughout the manufacturing process to verify adherence to quality standards and specifications.

-

Threading / Plain End / Any Other Requirement

Threads are applied or plain ends are formed, based on customer specifications or application requirements, ensuring compatibility with various fittings and connectors.

-

Final Inspection

The final inspection involves a thorough review of the finished products to ensure they meet all quality criteria and are ready for shipment to our customers.

Quality Policies

Quality Policies

Our ERW pipes and hollow sections ensure adherence to the highest quality standards and parameters. We focus on rigorous testing and compliance with industry regulations to deliver reliable and durable products.

-

We adhere to national and international standards for ERW pipes and hollow sections, ensuring compliance with ISO, ASTM, and other key industry certifications to guarantee product excellence.

-

Our electric resistance welded pipes undergo comprehensive quality testing, including chemical composition and mechanical performance assessments, to ensure they meet the highest standards of durability and reliability.

-

Our manufacturing process for ERW pipes is certified by leading authorities like SGS and TUV, a mark of excellence that reflects our credibility as an ERW Pipe Manufacturer committed to delivering products that meet global industry benchmarks for quality and performance.

-

Utilising state-of-the-art inspection technologies, we conduct thorough examinations of ERW pipes to detect any defects and maintain consistent quality throughout the production cycle.

-

We continuously refine our quality policies and processes based on industry advancements and customer feedback, ensuring that as an ERW Pipe supplier, our pipes and hollow sections remain at the forefront of quality and performance.

-

Our dedicated R&D team continuously works to reduce costs and improve operational efficiencies, ensuring the delivery of high-quality products while maintaining competitive pricing.

-

We have developed an in-house flux filtering plant that ensures zero iron content in flux, significantly enhancing product quality and performance.

-

Our innovative special additives, developed in-house, provide products with an extra shine, elevating the aesthetic appeal and ensuring superior finish across all applications.

FAQs

FAQs

ERW (Electric Resistance Welded) pipes are welded through a high-frequency electrical resistance process. They are commonly used in various applications due to their durability and cost-effectiveness.

An ERW hollow section is a type of ERW pipe with a hollow cross-section, available in square or rectangular shapes, ideal for structural and construction applications.

ERW pipes offer high strength, uniformity, and cost-efficiency, making them suitable for transporting solids, liquids, and gases across diverse industries.

As a leading ERW pipe manufacturer in India, Utkarsh India follows stringent quality control measures, including rigorous testing and adherence to national and international standards.

ERW hollow sections are widely used in construction, manufacturing, infrastructure, oil and gas, and transportation sectors for structural support and reinforcement.

Utkarsh India is a reputable ERW pipe supplier, offering a wide range of high-quality ERW pipes and hollow sections for various applications across India.

Key features of ERW pipes include high strength, precision in dimensions, and excellent weld integrity, making them ideal for structural and mechanical uses.

Utkarsh India utilises advanced production facilities, including high-speed tube mills and galvanising units, to manufacture ERW pipes that meet international standards.

Utkarsh India offers ERW pipes ranging from 15 mm to 400 mm in diameter and from 2 mm to 10 mm in thickness, catering to diverse application needs.

ERW hollow sections are used as structural elements in construction for their strength and versatility, supporting buildings, bridges, and other infrastructure projects.

ERW pipes offer advantages such as cost-effectiveness, uniform quality, and suitability for high-pressure applications, compared to other pipe manufacturing methods.

Yes, ERW pipes are suitable for high-pressure applications due to their robust welds and consistent quality, making them ideal for transporting fluids and gases.

You can place an order for ERW pipes by contacting Utkarsh India directly through their website or sales representatives for customised solutions and timely delivery.

Utkarsh India’s ERW pipes are certified by various national and international authorities, including IS, ASTM, ISO, and CE, ensuring high quality and reliability.

Why Choose Utkarsh India

Why Choose Utkarsh India

-

With over forty years in steel fabrication, galvanisation, plastic extrusion, and moulding, Utkarsh India has established itself as a leader in infrastructural manufacturing.

-

With in-house production of both MS and galvanised pipes under one roof, Utkarsh ensures high-quality products with precise end finishing, adhering to IS specifications and using the finest raw materials.

-

We use only premium Zinc for galvanising, ensuring superior corrosion resistance and durability, backed by strict testing standards like Mass of Zinc, Uniformity, and Adhesion tests for customer satisfaction.

-

Timely delivery of materials is one of our core strengths. We cater to a wide range of clients, including EPC contractors, municipal corporations, utility companies, and more, enhancing our brand reputation across India.

-

Utkarsh holds BIS licences for multiple Indian Standards (IS 1239, IS 1161, IS 3589, IS 4923, and more), ensuring compliance with national norms across all products for various industries and major projects.

-

Our state-of-the-art testing facility features Mechanical, Chemical, Hydro, and Online NDT/Eddy Current testing, along with an in-house spectrometer, ensuring top-quality output in every product.

-

Our steel tubes and pipes are engineered for high tensile strength, ensuring robustness and reliability in demanding applications like construction, infrastructure, and industrial projects.

-

Manufactured with high-quality materials, our steel tubes and pipes offer excellent resistance to corrosion, making them ideal for use in harsh environments and extending the lifespan of your projects.

-

With advanced manufacturing processes, our steel tubes and pipes maintain precise dimensions and consistency, ensuring a perfect fit for your specific requirements and enhancing overall project efficiency.

-

Our steel tubes and pipes cater to a wide range of industries, from oil & gas to transportation and manufacturing, offering versatile solutions for fluid transport, structural support, and more.

-

We offer tailored steel tubes and pipes in various sizes and specifications, allowing you to customise your order to meet unique project needs while maintaining quality and performance.

-

Every steel tube and pipe undergoes stringent quality checks, from raw material sourcing to final inspection, ensuring that only the highest standard products reach our customers.